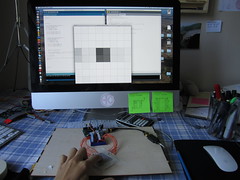

Finishing the matrix code (13.9.2011) (2012)

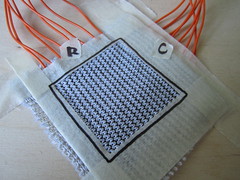

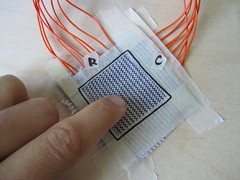

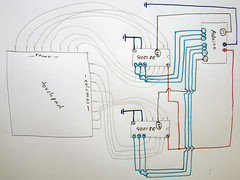

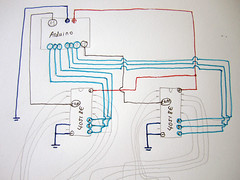

This first example of a 8×8 matrix was mostly for the purposes of getting the code for the multiplexer setup and the visualization done. This small prototype is made using knit needle-stripe conductive fabric from plug and wear. The conductive stripes in the fabric are knit with a very thin flexible wire. Unfortunately the wire was not that great to solder to (they have a fabric breadboard fabric, that uses a copper wire and is much better for soldering to), so I skipped every other conductive knit row. The nice thing about this fabric is that it can be industrially produced and the connections to the conductive traces can be soldered. The fabric is not very stretchy, but i could imagine that it could be made more so.

Video (now with captions!)

The next versions of this matrix will focus on stretch and getting it to work on the robot arm prototype. I think that the thin sheet of neoprene will work well, because it is stretchy but also strong enough to limit the bend of the joint, to a radius that it can manage. Although it could become a problem if it is not stretchy enough.

Another option is to use a thinner and more stretchy fabric like a stretchy nylon or jersey. The problems i see with this, is that the fabric will crunch and wear at the joint.